Home>Fasteners & Machined Components>Automotive Applications> Screws for Plastic

Automotive

Screws for Plastic

Links To Other Pages

On This Page

- TPlast30 Thread Forming Screws

- TPlast60 Tapping Thread Screws

- TPlast Hi Lo Thread Screws

- TPlast HITORQ Screws

- TPlast Sems Screws

EES-0041 (3 Pages pdf)

Screws-for-Plastic

Design Engineering Guide

_Cleaned.png)

TPlast30 Round Shank Thread Forming Screws

Coarse, sharply angled threads with round shank are used in plastics such as polypropylene, polycarbonate, acetal, polystyrene, and ABS to provide maximum holding strength with minimal stress. These high performance plastic screws are compatible with PT and Delta PT type screws.

![]()

These screws are best suited for soft plastics with thin bosses. Thread profile is 30º with expanded thread pitch.

Advantages: Great for soft thermo plastics. Low driving torque. Suitable for thin bosses. Good torsional strength.

Disadvantages: Not usable with thick sheets and J-Nuts. Lower torsional strength.

Features and Benefits

- 30º sharp threads

- Use in all types of plastics

- Reusable many times

- Reduces stripping

- Consistent driving torques

_Cleaned.png)

TPlast60 Tapping Thread Round Shank Type B Screws

Round shank, coarse spiral threads, and blunt tip facilitate use in plastics such as polypropylene and non ferrous castings. These plastic screws have reduced tip for easy entry.

![]()

Also called thread forming screws, these are commonly used in both soft and hard plastics. Thread profile is 60º with medium thread pitch. They are generally used with plastics having a modulus smaller than 3000 MPa.

Advantages: Ideal for soft and hard plastics, thermo plastics and thermosets. Consistent driving torque. Good torsional strength.

Disadvantages:Not usable with very thin thermo plastics

Features and Benefits

- 60º threads

- Metal and plastic uses

- Reusable many times

- Usable with J-nuts

- Good torsional strength

_Cleaned.png)

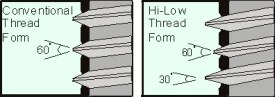

TPlast High Low Thread Screws Round Shank

The Hi-Low fastener, sometimes called "hi lo screw", with its unique dual thread form, improves fastener performance in a broad range of low density plastics. The 30° sharp high threads make a deeper cut into the material between the threads.

![]()

There is also a greater amount of material in contact with the high, sharp thread and the axial shear area is increased. All of this contributes to greater resistance to pullout and stronger fastening.

Advantages:Minimize cracking and splitting in brittle materials such as phenolic and glass-filled plastics. All drives, round shank, and blunt tip.

Disadvantages: Low torsional strength, unable to use with steel clip nuts.

_Cleaned.png)

TPlast HITORQ

These screws are designed for hard plastics with tapered bosses.

Advantages: Ideal for sheet metal, hard plastics and thermosets. Consistent driving torque. Great torsional strength.

Disadvantages: Not usable with thin sheets and J-Nuts. Higher piece cost.

Features and Benefits

- Thread size 4.5 mm

- 30 Degree sharp threads

- Single Lead

- Metal and plastic uses

- Reusable many times

- Reduces stripping

- Serrations eliminate loosening

- High torsional strength

_Cleaned.png)

SEMS

Screw assemblies (sems with free spinning washers) are available on several items. These are designed to support general assembly, industrial, automotive, and military applications. Sems screws decrease assembly time compared to using separate washers, provide for larger bearing surfaces for soft substrates, and eliminate instances of warranty failure due to missing washers.